Machine Vision Systems Deserve a Second Look by Auto Manufacturers Right Now. This is Why.

No one ever said manufacturing was easy. In fact, manufacturing processes are among the most complex to design, execute and optimize – even if you have a well-oiled machine doing a lot of the heavy lifting. There are so many moving parts to track, even beyond the production line, and a great deal of effort goes into maintaining line of sight into raw materials, finished goods, equipment, workers, suppliers, and other supply chain components that influence output. Oversights are more common than desired and not without consequence.

With so many people critically assessing manufacturers’ performance – from channel partners and consumers to industry and government regulators – it is important to do anything and everything possible to improve production quality and timing. There is literally no margin for error. Either you built something correctly or you did not. And delivery deadlines are unyielding thanks to contractual obligations to supply chain partners and inflexible customer expectations. When things don’t turn out as intended, you can’t just go back to the drawing board and start over. That’s actually what my team and I have been increasingly hearing from automotive brands and parts manufacturers lately.

With the economy starting to recover and production still slightly depressed, this is the perfect time to scrutinize and optimize processes as well as the systems supporting them – especially those dictating parts and goods traceability, driving inspections/quality control, helping to reduce waste, or influencing overall production and order fulfillment rates.

In many cases, the discussions we’re having are centered on industrial automation, as Just-In-Time Delivery, quality metrics, and product recalls are all major challenges right now. As we take a closer look at how well machine vision and fixed industrial scanning solutions are performing in the automotive space, we’re starting to notice a pattern – or an opportunity, as I prefer to see it.

The New Vision for Machine Vision and Fixed Industrial Scanning Solutions (from a Manufacturer’s Perspective)

It takes over 30,000 parts to build the average vehicle, and the design and assembly of each one must be perfect. It’s not just about keeping drivers happy, though. It’s about keeping them safe. If a gasket is missing, or a gear is missing teeth, any number of things could go wrong when that vehicle hits the road. Much like a supply chain, each vehicle’s performance is dependent on the flawless fabrication of each component and system. But it’s not easy for factory workers to see if everything from the doors and dashboards to the powertrain and pistons are present, much less properly seated, as they’re moving down the line. It’s also not reasonable to think the human eye could successfully confirm the proper use of sealants and adhesives or identify a design flaw in a tiny chipset, bead, or bolt without some help from high-resolution cameras.

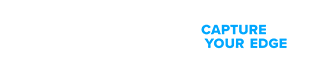

Thus, the benefit of modern machine vision systems. They can critically analyze parts, products and more in time-sensitive situations.

If the camera and software are working as they should, and operators are able to maximize their capabilities without much of a learning curve, it becomes very easy to inspect everything that passes by and make an instant pass/fail decision with confidence. The process is quite literally automated, with very little intervention needed by the system operator.

However, many legacy machine vision systems do not operate with the seamless simplicity and efficiency needed by modern production lines. Sometimes the camera resolution is poor, leading manufacturers to question the accuracy of the machine vision system and their ability to consistently detect defects while there’s still time to pull the parts or the vehicle off the line. In other cases, the older systems are processing images too slowly for the automotive production tempo demanded today – and most certainly for the factories of the future.

In general, the sentiment is that machine vision, though institutionally mandated in today’s Industry 4.0 environment, is putting more work on manufacturers’ plates than they can (or want to) handle. They want a system that is simple to setup, learn, maintain and even transform as needed to support a variety of applications.

In an ideal world, they would have a cross-platform industrial automation solution that could be configured to support any number of vision or barcode read applications with ease. Essentially, they want a machine vision and fixed industrial scanning system that is one in the same, which makes a lot of sense in this day and age. With the recent advancements in technology, it’s not necessary to install multiple solution components across facilities to automate parts verification, confirm the proper placement of a package label during pre-shipment quality control inspections, and track inventory movement down the line.

Today, the same device can be used to capture high quality images, scan multiple barcodes and generate process control metrics. This makes it easy to provide real-time confirmation of where parts are located, if a component was properly assembled, and if manufacturers and/or suppliers are fully compliant with the many different mandates defined in contracts, regulations, and other quality control measures.

In short, the ideal solution for industrial automation in the automotive space is finally becoming a reality.

See What’s Now Possible When You Only Have to Integrate, Configure, Learn, and Maintain Just One Industrial Automation Platform

Every automotive manufacturer I’ve spoken to recently is concerned about four things from either an operational or technological perspective: complexity, precision, accountability, and speed. So, for the purpose of this discussion, let’s hone in on the specific challenges and how new industrial automation solutions can solve for each:

Challenge #1: There are a number of different production processes and systems to manage, and several of them rely on either fixed industrial scanners, machine vision cameras or a combination of the two. They need to streamline these systems, which I’ve already noted. Beyond that, they need to streamline and simplify their parts intake, quality control and even outbound logistics processes.

Solution considerations: Having one platform with both barcode reading and machine vision capabilities makes it easy to transform and optimize processes at your pace. You can focus the solution to address each challenge at hand. It’s even better if it uses standardized communications protocols, supports both 1D/2D code, and offers a vast machine vision library. Just look closely at the solution’s decode capabilities to make sure you can trust the data being generated and stored in your systems. And be sure it can automatically create a digital record – whether of images or inventory movements – to help populate shipping manifests, inventory management systems, and even invoices. That removes one more (often manual) step in production, storage, and shipping workflows.

###

Challenge #2: There is a low tolerance for assembly errors, and parts are either compliant or they aren’t. It’s also vital to check the date and lot code of every part/package/pallet coming and going.

Solution considerations: It’s hard to appreciate the level of nitty gritty detail that needs to be evaluated for each part, in a split-second no less, until you see it for yourself. We have been working with an auto manufacturer to refine its machine vision solution for the inspection of engine, radiator and housing components. There are three caps that must be present to pass inspection and continue on to packaging. If even one is missing, or a cap is in the wrong place (denoted by color and other decoded data), the engine component will be rerouted to a re-work line. Now, this is a larger part and someone could probably visually inspect this item somewhat easily – but not quickly. This engine goes in a mass production vehicle, and millions of these components have to be inspected each year. Considering it’s one of ~30,000 total items that must be inspected, the machine vision camera is the best solution – especially if properly optimized.

Moreover, the manufacturer’s housing components each have 11 bolts that must be inspected before they can go to the driver. So, the machine vision camera needs to be able to correctly verify the presence and design compliance of each bolt (not an easy task) with perfect accuracy. Otherwise, if the component is improperly passed, damage could be done when the driver tries to torque the bolts into position. That’s why it’s imperative to have best-in-class algorithms like pattern recognition, edge detection, and blob analysis to ensure product meets demand.

Now, think about this from a labeling/mark perspective. Each part is going to have a direct product mark (DPM), and batched materials are going to have additional labeling mechanisms – all of which are rich with item and status information. If you have ever tried to take a good photo of an object in motion, you know it’s no easy feat. That’s why machine vision and fixed industrial scanners need to be thoroughly vetted for their ability to read any barcode for parts verification. They should also have OCR tools capable of verifying date lot codes with system information for parts compliance and warehouse management system (WMS) reconciliation.

###

Challenge #3: When parts are non-compliant, or the wrong item was either received or shipped, there are repercussions. So, the goal is to get ahead of issues to avoid recalls, financial losses, or worse.

Solution considerations: Because industrial automation solutions such as the one Zebra offers can capture and evaluate both barcode data and images, it’s easy to identify defect patterns or process inconsistencies – and hard for anyone to argue with a claim of non-compliance. If it’s a non-compliant part, the supplier or production line system can be traced using the direct part mark or other identifier so the issue can be investigated and (hopefully) resolved right away. Stored images can be retrieved for reference, if needed. This results in more uptime and less scrap in the long run. If it’s an assembly issue, the team can be retrained as needed. And if it’s a labeling issue, the correction can be made before the package goes out the door. Of course, if there is an issue, the hope is that by solving the first challenge above, recall notices can be issued swiftly as records will be easy to retrieve.

###

Challenge #4: Processing parts fast enough for production runs is no simple task, especially given the growing sales volume and demand for greater customization. (I literally got an email from a major U.S. auto manufacturer five minutes ago encouraging me to “custom order” my next vehicle from them.)

Solution considerations: This one is pretty straightforward: You must have cameras and scanners that operate in continuous mode. It’s the only way to ensure multiple successful decodes per second with accuracy, no matter how many different vehicle models – and how many more different parts variations – are needed to fulfill custom orders such as the one I might place sometime in the future.

A Final Thought (and Call to Action) for All Auto Manufacturers

If your current machine vision cameras and fixed industrial scanners are not doing what you need them to do, or if they’re proving difficult to use or manage, it’s time for a change. Let’s sit down and see how best we can fill those capability gaps, increase your process control, and simultaneously simplify and speed up everything from quality control inspections to non-compliance investigations. In some cases, we may be able to adapt your existing systems by integrating new cameras or scanners. Or you may realize it’s better to invest in a completely new industrial automation system. Many customers have been shocked to see just how many different ways Zebra’s dual-mode devices can be applied using a single software platform. They’re also relieved to learn how easy it will be to scale the solution – or switch between vision and barcoding applications – as operational needs change.

If you haven’t reached out to our team yet, I hope you will soon. We can schedule a discovery session to review your current challenges and goals, as I know they may not be exactly the same as those I mentioned above. (You may have 10x as many.) In the meantime, you can learn more about how Zebra has been innovating to deliver on your industrial automation vision in this blog post and this podcast.

###

Related Resources:

Donato Montanari

Donato Montanari is the Vice President and General Manager, Machine Vision, at Zebra where he is responsible for fixed industrial scanners, smart cameras, machine vision hardware and machine vision software.

Donato has more than 25 years of experience within the Imaging and Industrial Automation industries and has brought to the market more than fifty new products throughout his career.

Previously, he served as CEO at deevio, where he managed all aspects of the business. Donato holds a MS in electronics engineering from KUL Leuven, Belgium and a BS in electrical engineering from Universita’ di Pavia, Italy. He is a Board Member of the Machine Vision Chapter of the VDMA in Frankfurt, Germany.