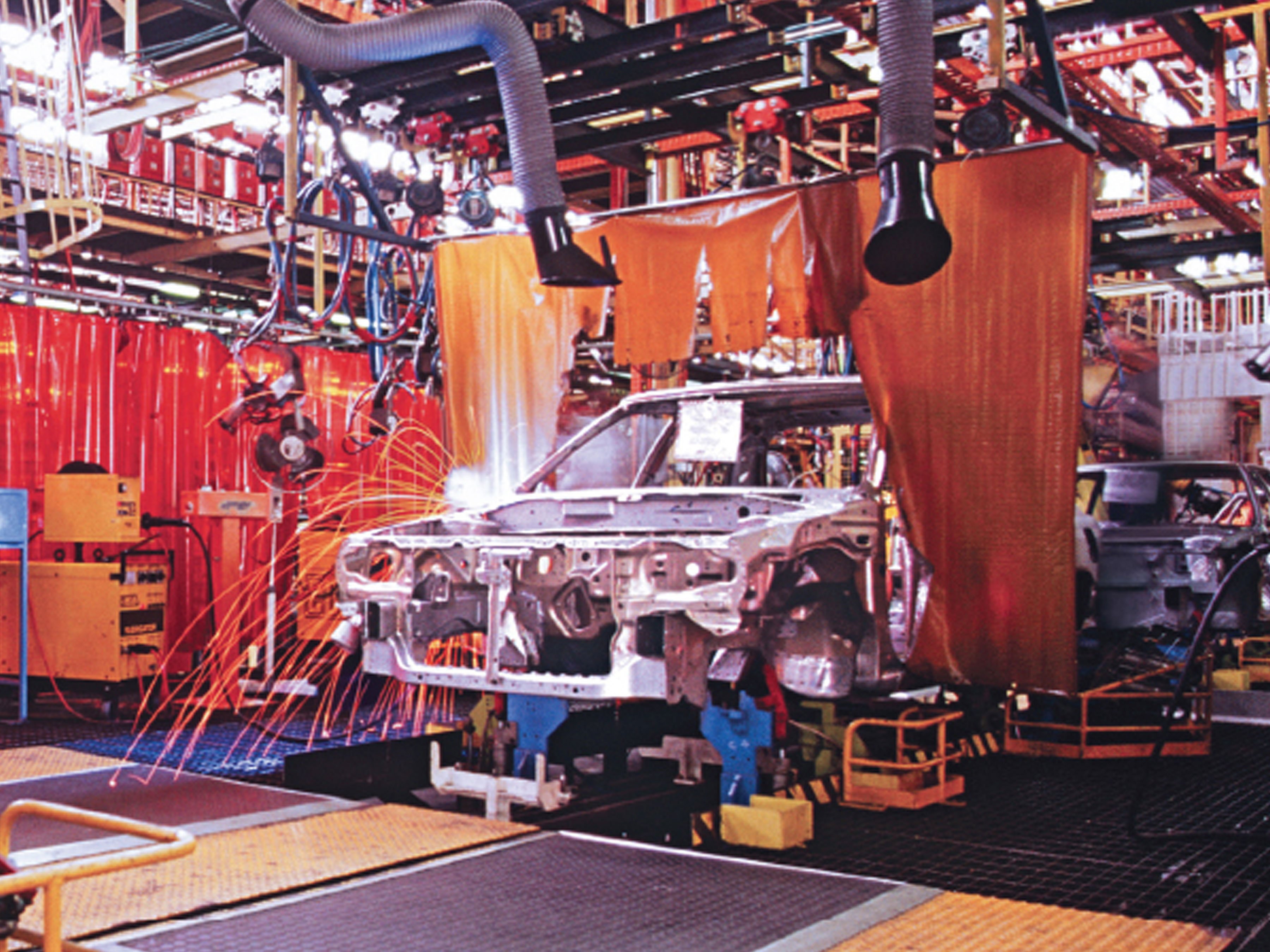

Company-Wide Real-Time Location System Drives Efficiency at Ford Motor Company

Ford Motor Company faced the complex challenge of efficiently managing and locating thousands of vehicles and parts within its supply chain. Misplaced items could disrupt manufacturing processes, delay product delivery, increase inventory costs and lower productivity.

Zebra Success Story: Ford Motor Company

Overview: Automotive Challenge

To address these issues, Ford implemented Zebra's wireless Real-Time Locating System (RTLS) across 35 of its manufacturing plants in North America and Europe. The system uses low-power radio frequency tags, antennas and web-enabled software to track inventory and vehicles with high precision.

Benefits / Outcomes

- More efficient use of labor

- Implementation cost savings of approximately $200,000 to $500,000 per facility

- Fast installation with a call system coming online in a matter of weeks

- Proven reliability with performance approaching Six Sigma ratings

- May reduce the time that vehicles sit on the lot by at least one day

Customer

Ford Motor Company

Industry

Manufacturing

Solutions

About Ford Motor Company

Knowing what you have and where it is within the supply chain at any given time should be straightforward. But consider an enormous manufacturer, such as Ford Motor Company, which must manage tens of thousands of items, and suddenly the seemingly simple task of knowing what you have — and where it is — becomes staggeringly complex.

The Challenge

Temporarily misplaced items can stop a manufacturing process, delay the delivery of products, result in excess or obsolete inventory and contribute to a loss of productivity. And as companies implement lean manufacturing processes, the value of real-time information for every container of inventory flowing through the supply chain is critical.

To meet these challenges, Ford Motor Company implemented a wireless Real-Time Locating System (RTLS) from Zebra Technologies at several of its plants throughout North America and Europe. The system is driven by wireless tags, fixed position antennas and Web-enabled software. The system locates and tracks inventory using extremely low-power radio frequency tags and a communications network. Antennas positioned inside and outside the factory receive tag transmissions and deliver tracking information to a computer. The system then identifies the location of the tag within 10 feet of its exact position.

By implementing VTMS, we can now locate exactly which vehicle we want or need in a matter of seconds.

The Solution

Ford initially implemented RTLS in February of 1998 to track materials within a 250,000-squarefoot area of its Van Dyke facility in Sterling Heights, Mich., which produces more than nine million components annually for Ford cars and trucks. Utilizing the same installed infrastructure of antennas, Ford and Zebra then co-developed a wireless “call” system known as Zebra WhereCall to bring parts to the line as needed. Roughly 35 Ford Motor Company manufacturing plants worldwide use the WhereCall technology. Most recently, Ford implemented a third application of RTLS — Zebra’s Vehicle Tracking and Management System (VTMS). The use of VTMS began as a pilot project in June 2000, at Ford’s Michigan Truck Plant, which assembles thousands of vehicles daily. The pilot was completed in February 2001, and a version of the technology — called Quick VTMS — has been rolled out to all manufacturing plants in North America.

Imagine trying to locate one car in a vast lot filled with 2,000 to 3,000 nearly identical vehicles, and you can understand the impetus behind the need for Zebra®’s VTMS. This application provides constant visibility and management of vehicles from final assembly to shipping, making it easy to instantly locate specific vehicles to fulfill dealers’ custom orders or to identify any automobiles on hold for quality control. “By implementing VTMS, we can now locate exactly which vehicle we want or need in a matter of seconds,” said Al Ver, Ford Motor Company Vice President of Advanced and Manufacturing Engineering. “Before we began using VTMS, the same process could easily take hours.” A single vehicle manufacturer may spend more than one million dollars each year locating and managing inventory within its delivery chains. It is estimated that the integration of VTMS will reduce the time that vehicles sit on the lot by at least one day.

While Ford’s Van Dyke plant has adopted lean manufacturing principles, parts often end up being stored until needed at the line. RTLS tracks each item during its time in the plant so that personnel can always locate them quickly. Containers can be permanently affixed with a wireless Wheretag, each with a barcode that is associated with the product ID of the item. Every four minutes, the tag transmits its location to continually update the warehouse management system on its location. The tags can remain on the container even after leaving the facility, as they have a battery life expectancy of seven years.

When transmissions are shipped to the Wayne Assembly Plant in Wayne, Mich., another Zebra RTLS picks up the tag transmissions there and begins tracking as the racks reach the docks. “This was one of our biggest tests of the location accuracy and robustness of the tag,” said Ford’s Ver. “For a technology that depends on radio transmissions, this is a very harsh environment: There’s a metal transmission rack, a metal environment, a metal part that goes into the rack, and lots of racks stacked upon one another, all in a facility with a lot of heavy machinery operating.”

RTLS also makes it easy for line workers at the plant to request fresh supplies of materials. Most major automakers have adopted the paper cardbased Japanese Kanban system for bringing parts to the assembly line. Zebra and a Ford subsidiary, Ford Global Technologies, jointly developed a special call functionality that has greatly improved the efficiency of traditional material replenishment processes and has enhanced the capabilities of the locating system. Ford now places WhereCall devices at assembly stations. When supply of a specific part reaches a pre-determined replenishment level, the line worker presses the WhereCall button that sends a signal to re-stock that particular part so that the line will never run out of parts. This process eliminates the need for replenishment workers to travel routes to pick up Kanban cards and eliminates some lag time from the process, further minimizing lineside inventories.

When an operator presses a WhereCall button, a light on the unit flashes 10 times to confirm the transmission and the timer begins counting. With multiple parts at some assembly stations, the timer helps remind workers which tags have been activated and how much time has elapsed since each call was made. During shift changes, this is extremely beneficial as it eliminates confusion and potential overstocking of parts. Using the same local infrastructure of antennas mounted in the plant ceiling that pick up the wireless tag pings, the WhereCall message for parts is conveyed to the WhereNet server, which determines the location of the call and the part that needs to be replenished. The data is then passed onto Ford’s SMART System, which in turn displays a message on a touchscreen computer. The system ensures that drivers never have to leave the cabs of their lift trucks as they receive the order, pull parts from inventory, and deliver them to the exact location of the line-side operator who initiated the WhereCall just a few minutes before.

The Zebra Difference: Outcome and Benefits

The wireless nature of the system offers tremendous flexibility and helps assure that the line is reliably stocked with materials as needed. Ford has achieved impressive results through its use of the technology:

- More efficient use of labor

- Implementation cost savings of approximately $200,000 to $500,000 per facility over hardwired systems

- Fast installation with a call system coming online in a matter of weeks

- Proven reliability with performance approaching Six Sigma ratings

As a testimony to this technological breakthrough, Ford Motor Co. awarded the co-development team from WhereNet and Ford with the Henry Ford Technology Award in October 2000. The call system application has helped Ford engineers leverage the benefits of the container locating system in new ways with little additional investment, because the systems share the same transmitting and receiving infrastructure. As Ford adds more applications, the costs per application come down and the savings increase dramatically.

Impressed by the results achieved through the technology to date, Ford gave full corporate backing for use of the technology in plants worldwide. “It has the accuracy and the potential we need,” Ver said. “Our experience at the Van Dyke plant has fully proven to us that it can meet and even exceed our expectations. In today’s competitive automotive market, WhereNet gives us a valuable edge.”